Home > Company Introduction

Company Overview

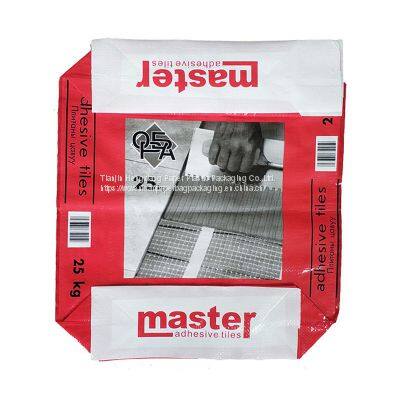

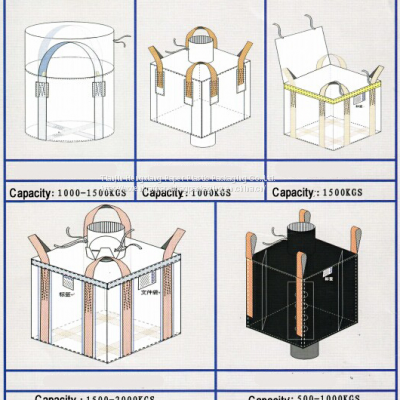

· Production process of 25kg 50kg kraft paper plastic pp woven composite porland cement bags/sack:· The following is the whole process to making the Ad*Starkon block bottom valve sack:· Extruding PP particle---------Drawing and cutting PP film-------thread the PP tapes-------Weaving pp tapes to tubular fabric-------Coated with PE film- offset or flexo Printing the body-------hot air welding the tubular body and bottom and top patches and valve--------Inspecting the strength tensile and air permeability-package· Advantage of 25kg 50kg kraft paper plastic pp woven composite porland cement bags/sack:· Compared with the traditional 3-ply multi-wall paper cement bag and ordinary pp woven plastic bag, the Ad*Starkon block bottom valve sacks have the following advantages:· 1. Economical- lower sack weight save raw material as against the paper bag and PE bags.· 2. Cleaner environment - There is no glue adhesive during the whole production process.· 3. Less risk of damage - high strength tensile pp woven and high speed filling.· 4. Easy handling-the brick shape box shape is easy to palletizing.· Quality control of 25kg 50kg kraft paper plastic pp woven composite porland cement bags/sack:· In order to produce the high quality Ad*Starkon block bottom valve bags, the following is our effort to control quality:· 1. From material: using 100% original high strength pp material. not recycled or wasted pp material.· 2. For fabric: control the strength tensile and density of pp tapes to satisfy the loading capacity.· 3. Inspection: using the machines to test the strength tensile and tearing function after finish the goods.· 4.Drop test: for safe factor, for each batch of products, will test the air permeability.We work as an unique exporters for all types of FIBC products. We manufacture FIBC to create end to end solution for industrial packaging. Our manufactured Jumbo bags are use for bulk packaging of dry flow able materials. Here PP plastic granules are converted into finished FIBC as 4-loop jumbo bag, single loop or double loop bag, ventilated bag, tunnel loop bag, conical bag, cross corner bag or container liner bag as per client needs and packaging requirements.Sales Manager:DanielMobile Phone:86- 13802155833E-mail:tjwhoking@163.comQQ:490045876SKYPE:antonio87455WeChat:13802155833WhatsApp: 86-13802155833

-

ManufacturerBusiness Type

-

2003Year Established

-

1,000-3,000 square metersFactory Size

-

US$2.5 Million - US$5 MillionAnnual Export Value

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

51 - 100 People Total Employees

-

21-50 People Sales Staff

-

10-20 People Quality Inspectors

-

HACCP, TL900, QS9000, SA8000, ISO9001, ISO9004, ISO17799, ISO9000, ISO14000, ISO10441, ISO16949, TS16969, ISO19011:2000, OHSAS18001, Others Product Certifications

-

US$2.5 Million - US$5 Million Annual Export Value

-

North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, Domestic Market Main Markets

-

guangzhou, tianjin, qingdao Port of Shipment

-

Packaging Paper Main Industry

-

Our ServicesAd Star polypropylene bags have brick-shaped form, convenient for palletizing and storage; ▪ Ad Star valve bags have high barrier properties and inhibit odors; ▪ Ad Star polypropylene bags prevent oxidation of the product with air; ▪ valve bags made of polypropylene have great strength and resistance to tearing; ▪ Ad Star box-shaped bags have high mechanical strength and withstand impact; ▪ operational range from -70 °C to +100 °C, resistant to alkalis, water and organic solvents; ▪ Ad Star polypropylene bags are not subject to erosion and have light weight; ▪ polypropylene box-shaped bags do not decompose with active substances inside; ▪ Ad Star cement valve bags have excellent dielectric characteristics; ▪ Ad Star valve bags have high impermeability and resistance against moisture, 100% recyclable; ▪ polypropylene box type bags with valve is an eco - friendly packaging;

Our ServicesAd Star polypropylene bags have brick-shaped form, convenient for palletizing and storage; ▪ Ad Star valve bags have high barrier properties and inhibit odors; ▪ Ad Star polypropylene bags prevent oxidation of the product with air; ▪ valve bags made of polypropylene have great strength and resistance to tearing; ▪ Ad Star box-shaped bags have high mechanical strength and withstand impact; ▪ operational range from -70 °C to +100 °C, resistant to alkalis, water and organic solvents; ▪ Ad Star polypropylene bags are not subject to erosion and have light weight; ▪ polypropylene box-shaped bags do not decompose with active substances inside; ▪ Ad Star cement valve bags have excellent dielectric characteristics; ▪ Ad Star valve bags have high impermeability and resistance against moisture, 100% recyclable; ▪ polypropylene box type bags with valve is an eco - friendly packaging;